Coloring Fashion on our Blue Planet

Posted on 22/04/2024

Water-saving technologies from pre-treatment to finishing

From field to factory to fashionista’s wardrobe, the garment and textile industry is famously water-hungry.

New research suggests that fashion is responsible for the consumption of 79 trillion liters of water annually—enough to meet the water needs of 27% of the world’s population at the World Health Organization optimal standard of 100 liters per person per day. Fashion also contributes about 20% of total industrial wastewater. If not properly treated before discharge, this wastewater can be harmful to people who have to rely on polluted water sources. It can also negatively impact aquatic life.

While top global brands are driving water stewardship across the textile value chain today, the future will likely see all brands and their mill partners coming under pressure to do more.

The availability of water is already a serious issue in many parts of the world, and especially acute in key textile producing regions. Climate change and increasing public awareness of water issues, such as the true cost of inefficient water use and wastewater pollutants, will only amplify the risk to brands. It is not difficult to imagine water shortage issues causing disruption to textile production and global supply chains in the future.

Against this backdrop it is imperative that mills find ways to reduce water use from production to consumption, thereby saving resources, and to eliminate toxins and contaminants from their production processes, thereby making wastewater easier to treat and safely discharge.

As a partner to textile and fashion brands and mills worldwide, Archroma develops water-saving innovation and cleaner chemistries to help move the industry towards a greater focus on sustainability and a better understanding of consumer aspirations.

Archroma Super Systems+ are fiber-specific solutions that deliver process efficiency and intelligent effects that meet different sustainability targets and consumer demands. The Archroma Impact Matrix empowers mills and brands to align their sustainability goals with their choice of Super Systems+ and make informed decisions around resource-saving processing, cleaner chemistries and improved end-use durability – separately or in combination.

Archroma’s DENIM HALO is a new concept for denim production that is both eco-friendly and simple. This innovative approach includes a patent-pending resource saving pretreatment and dyeing processes that results in the most sustainable laser friendly and easy wash denim, enabling considerable reduction in environmental footprint of denim finishing process while achieving the desired look.

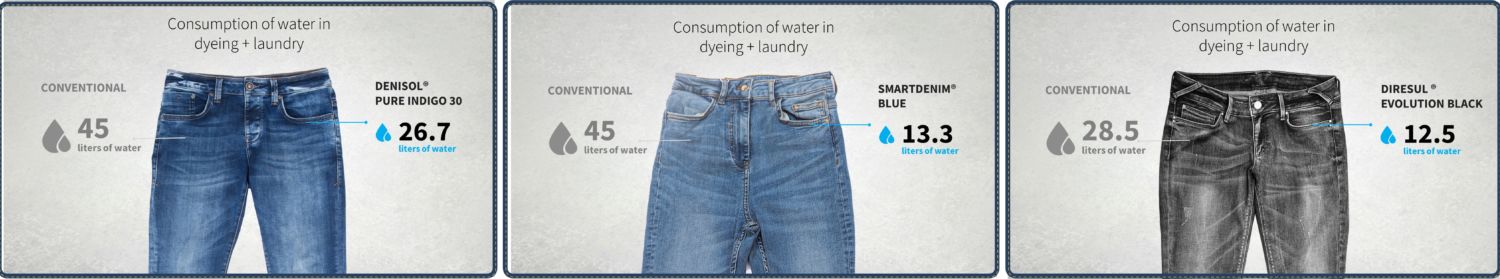

For classic blue denim jeans, water savings of up to 40% compared to conventional dyeing and finishing processes can be achieved with the aniline-free (1). DENISOL® PURE INDIGO 30 LIQ dyes, while savings up to 70% are possible with the DIRESUL® SMARTDENIM BLUE pre-reduced sulfur dye for a unique blue denim look. For black denim jeans, DIRESUL® EVOLUTION BLACK uses up to 56% less water during dyeing and laundry processes. It can be used to create unique shade and wash-down effects with an overall impact reduction of up to 57% compared to standard Sulfur Black 1 liquid in synthesis (2).

Beyond denim, Archroma has water-saving innovations for all types of fibers. The revolutionary AVITERA® SE technology enables water savings of up to 50% on cellulosic fibers and blends, with an improved cost-to-performance ratio for dark and extra-dark shades. For polyester and its blends, ERIOPON® E3-SAVE is a next-generation auxiliary that combines pre-scouring, dyeing and reduction clearing in a single bath to achieve substantial savings of water, energy and time. Results from bulk production show water savings of more than 50%.

For textile printing applications, Archroma’s cutting-edge technologies and system solutions enable its partners to produce vibrant designs and colors, with a focus on quality, sustainability and performance. Solutions range from spin finishes and sizing systems that improve productivity and reduce effluent load to water-saving pre-treatment, pigment printing, reactive printing, disperse printing, acid printing, digital printing, washing off and finishing.

The fashion and textile industry is showing an increasing preference for safer chemistry that keep unwanted ingredients out of the supply chain, off the fabrics and away from consumers, while also maintaining production efficiency and end-use performance. At Archroma, this shift is known as COMPLIANCE+, where a curated range of dyes, inks and chemicals incorporate innovative technologies specifically developed to remove (3) harmful or regulated substances typically found in foundation-level alternative products in the market. COMPLIANCE+ anticipates future restrictions and ensures Archroma's products are always compliant with upcoming environmental standards.

As mentioned above, DENISOL® PURE INDIGO is free of aniline, a chemical that is beginning to appear on restricted substances lists because it is known to be toxic to aquatic life.

For woolen fabrics, Archroma’s LANASOL® dyes are a consistent, safe and reliable alternative to after-chrome dyes. These dyes deliver optimal fastness and wool quality while outperforming chrome dyes to achieve substantial savings of water and energy. With no chrome in the wastewater to take care of, they help mills and brands meet Zero Discharge of Hazardous Chemicals (ZDHC) standards while also lowering wastewater treatment costs.

Archroma is also pioneering more sustainable and cost-efficient leather production. In partnership with Trumpler, a leader in leather chemicals, it has recently introduced the groundbreaking DyTan® process for high-performance leather. Based on Archroma’s patented AVICUERO® system, it is free from metal salts and reactive aldehydes and delivers significantly shorter processing times and significant water savings. It also eliminates the pickling process and the use of common salt leading to improved effluent discharge loads.

Producing garments that last longer and need less frequent home laundering is another way that brands and mills can help reduce the overall environmental impact of the industry.

Archroma’s Odor Control system includes the patented Sanitized® Odoractiv OA10/OX20 to neutralize odors, preventing pungent “permastink” from building up on sportswear and other clothing made of polyester, cotton or nylon. This unique non-biocidal technology supports consumers to wear garments for longer between washes. It is also wash resistant up to 50 home launderings, giving garments a longer life.

Archroma also has an extensive portfolio of fluorine-free durable water repellents (DWRs) for sustainable rain- and stain-resistance. These finishes help garments stay looking new for longer, reducing the need for home laundering.

For example, the new bio-based PHOBOTEX® NTR-50 is designed to provide excellent water repellence on all kinds of fibers while achieving a very soft handle. It is based on 50% renewable carbon content based on ASTM D6866 and is free of per- and polyfluoroalkyl substances (PFAS) and formaldehyde. While offering good wash durability, PHOBOTEX® NTR-50 LIQ can be combined with a crosslinker like ARKOPHOB® NTR-40, which has a biocarbon content of 40%, to further boost wash and/or dry-cleaning resistance.

Alongside all of these innovations, increased supply chain transparency is also required. Archroma’s ONE WAY Impact Calculator enables brands and mills to track water-related data. The online Safe Edge+ portal provides access to the regulatory and compliance status of every Archroma product.

These tools support Archroma customers and their partners to select chemistries with reduced environmental impact and optimize their production processes to save water, helping the fashion and textile industry become more planet conscious.

[1] Below limits of detection according to industry standard test methods

[2] Life Cycle Analysis by Ecoterrae

[2] Below limits of detection according to industry standard test methods

Sources

Nature Reviews Earth & Environment: https://www.nature.com/articles/s43017-020-0039-9

The Environmental Impacts of Fast Fashion on Water Quality: A Systematic Review: https://www.mdpi.com/2073-4441...

Affiliations & memberships

Archroma are proud members and/or partners with the following organizations