- Packaging Technologies

- /

- Solutions

- /

- Process Chemicals Paper

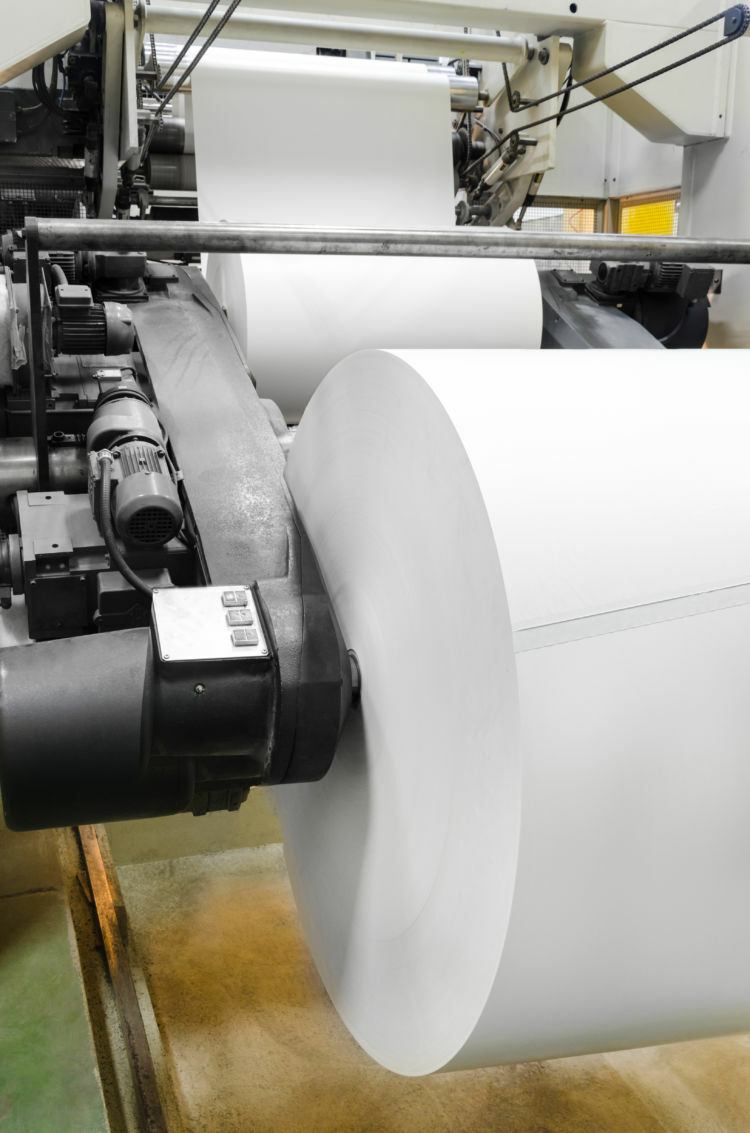

Process Chemicals Paper

By combining our focused product range with the application services of our paper experts around the globe, we aim to improve the production processes for our clients.

Papermakers using recycled paper in their production process can wave goodbye to “stickies” and look forward to cost-efficient manufacturing with Archroma’s pioneering Deposit Control Program.

Our fixatives guarantee deep and brilliant shades, reduce two-sidedness, improve dyestuff yield and the fastness properties of the dyes. Further gains in productivity are possible with Archroma’s retention and foam control solutions for pulp and papermakers.

In addition Archroma provides efficient solutions to increase wet and dry strength of paper, tissue and packaging.

Unsticking the potential

Pitch and stickies are the bane of paper production and recycling.Our special polymers from the Cartaspers® range solve that sticky old problem in different ways.

Cartaspers® PLH is a highly efficient mildly anionic polymeric surfactant for the passivation of pitch and stickies in pulping and papermaking operations. It is specifically designed for high performance in soft water environments.

Also of note, Cartaspers® PSM which is a non-ionic, biodegradable hydrophilic polymer with a high affinity for hydrophobic surfaces. Its unique properties provide a myriad of uses in the paper industry.

Cartaspers® SCS is a novel water based polymer emulsion for the wet-end prevention of stickie contamination which improves paper machine cleanliness and runnability.

Cartaspers® is easy to use, effective in a wide variety of environments and reducing negative downtime effects of stickies which leads to increasing productivity of paper production.

Questions about our solutions?

Reach out here and will get back to you as soon as possible.

Product availability may vary by country or region. Some products may not be available in certain markets. Our team is always on-hand to help – please contact us to discuss.

Archroma are proud members and/or partners with the following organizations